High temperature effluents

High temperature effluents

High temperature effluents generally come from laundries, cart washing or sterilization stations and any other service discharging effluents at more than 30 ° C.

To limit the risks of pathogens and burns, the regulations recommend that the temperature of these effluents be below 30 ° C before being discharged into the common network.

The treatment process:

- Route the effluents to storage tanks in a dedicated room

- Lower the temperature by an automated cooling cycle with 2 possibilities

- Passage of effluents through buffer tanks by adding cold water

- An exchanger system to recover and recycle water for other purposes in the establishment. - Evacuate the effluents once the authorized temperature has been reached, i.e. maximum 30 ° C

MWT offers you a full offer

:

Upstream :

- We advise and support you in the feasibility study of the project

- We manufacture tanks, skids and electrical boxes in the workshop.

- The controller is programmed and the processing station equipment is factory tested before shipment.

Our products:

- Temperature-resistant, made-to-measure PPH tanks, shipped whole or boilers on site

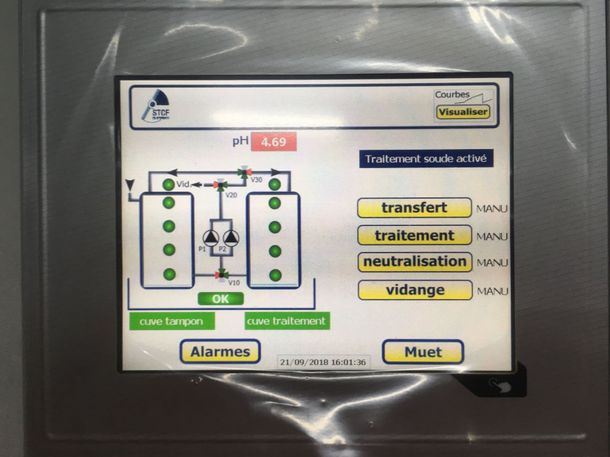

- A PLC with touch screen for remote control and monitoring of treatment.

- An exchanger for recycling calories and preheating the establishment's cold water

- A level and overflow probe

- A temperature probe

- A PPH retention tank

- A leak detection probe

- Alarm relay to the GTC / GTB

- Remote level and temperature indicators for viewing the level in the user department or on the security PC

Our services :

- Turnkey installation with : hydraulic connections, filling, calibration, settings, commissioning

- Training : We train future users of the treatment station as well as the establishment's technical service team

- Maintenance : Throughout the life of your equipment, we carry out maintenance operations, expansion work or additional functions .

Associated regulatory texts:

Treatment of

hospital effluents:

- CBRN

- Bacteriological

- High temperature

- Radioactive

Title of the slide

Écrivez votre légende iciButton

Preserving Humans and the Environment

in compliance with the law!

Contact us

Sales department: + 33 6 71 31 08 56

Technical support: + 33 6 07 86 95 31

E-mail : mwt@medicalwater.fr

22 quai Arloing, 69009 Lyon - France